STORY#02

After the bankruptcy of Lehman Brothers, demand for lower prices is growing increasingly. As a result, dark clouds are looming over the Japanese small and medium-sized manufacturing industry due to their high-cost. Until just few years ago, Mizuki was in a crisis of being told by the customers that “Your products are very good, but your prices are too expensive.” Therefore, we are gradually working hard on cost reduction in the last few years. Our efforts of steady cost reduction is paid off, and we are finally able to offer a low price to customers of the world. So, what are Mizuki’s secrets of price competitiveness that also works overseas? Mr. Nobuhiko Segawa, the group leader of the 2nd group in Manufacturing Technology Department, reveals the secrets.

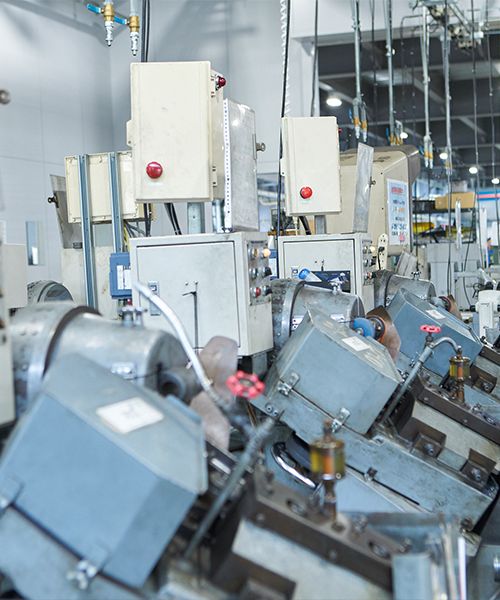

Lower the fixed costs of manufacturing machinery

It is said that the high-cost structure of Japanese companies is caused by the labor cost. Also, the prices are so high in Japan that it is difficult to suppress the labor cost, which puts Japanese companies in a disadvantaged position in cost competitiveness. Yet, Mizuki discovered there are other ways of reducing the cost other than lowering the labor cost. And, that is reducing the equipment fixed cost.

“We realized that we would not be able to compete with the price by manufacturing products with purchased pricy machinery, so we have started to maintain our own machinery since a few decades ago. We also devised methods for substantial remodeling of the machinery to obtain a performance equal to or even better than that of newly purchased machinery at a very low cost,” according to Mr. Segawa.

For instance, Mizuki remodeled the existing machinery to achieve functionalities of brand new machinery which costs nearly 10 million yen. By doing so, Mizuki was able to suppress the equipment costs significantly. Mizuki has engineers who are capable of remodeling the machinery themselves, and that’s one of the secrets of Mizuki’s price competitiveness.

Development of Original Rolling Machine

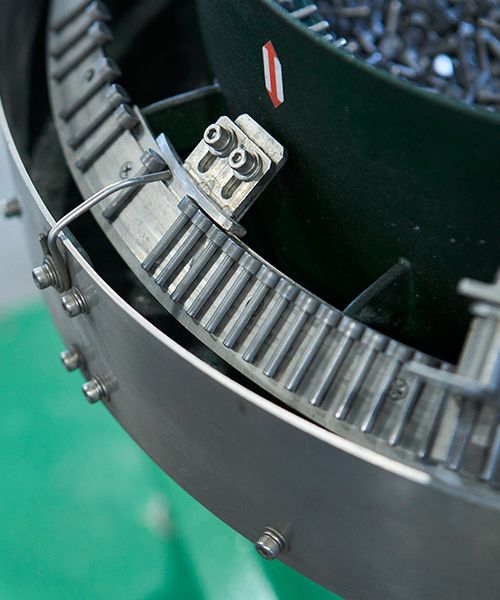

“We are not only maintaining or remodeling the machinery, but also trying to develop our own rolling machine.”

A few years ago, Mizuki had only 15 micro-sized rolling machines, and was barely enough to deal with the monthly requirement of 50 million units. Even though the needs for ultra micro-sized screws of M0.6-0.8 have increased considerably, our capability of mass production was only limited until M1.2.

“The rolling machine, which can produce ultra micro-sized screws efficiently, is not commercially available; we realized there is no way but to develop it on our own“

Mr. Segawa called for the technical staff right away and started the design process of their own rolling machine. In order to reduce cost, housing of the machine is made by welding a sheet metal; and the slide parts, which usually wear down heavily, are parts that can be replaced by commercially available metal parts. In the manufacturers’ point-of-view, they devised details in all aspects, such as easy to use and easy to run maintenance, while designing the machine. According to Mr. Segawa, the parts feeder to flow screws one by one is of particular difficulty in the design process. Because the parts are so tiny, the way to flow efficiently becomes the decisive factor.

“We researched on the easiest shape of flowing screws, and finally was able to build it on our own.”

Although it took a half year to assemble the machine, its result boasts a more than 100,000-unit production capacity per day. Later on, four remodeled rolling machines and three newly built ones for general-purpose products of M1.6-2 were added to the production lines. All of these machines contribute to a big role of cutting down the costs.

Improvement of Production Efficiency and Accuracy Absorb the Labor Costs

To absorb the differences of labor costs, lowering the equipment fixed cost is not the only method. Significant improvement in production efficiency is another vital process in Muzuki.

“The ultimate goal of developing our own rolling machines is that we are pursuing the technologies of the rolling machine to function unattendedly, speed up as much as possible, and produce products smoothly.”

The labor cost per product is considerably reduced because speed of Mizuki’s production line has increased, and can run smoothly and unattendedly night and day.

In addition, accuracy of the production machine is increased by repeated maintenance. Mizuki’s engineers know the state of the machine by watching the metal powder and listening to the sound caused when making a thread. Maintenance is applied for even just a little problems occurred. By doing so, the rates of producing defect products certainly drops a lot in Mizuki.

“All employees are striving for making superior products. Therefore, we are able to cut down the costs as a result of reducing the defects.”

The persistent effort appears like a detour, but it actually increases the price competitiveness of Mizuki.

Pride of the Engineer

“We realize it is unusual for a screw factory to even manufacture a rolling machine. When the plan of building a rolling machine was proposed, we took a consideration. And, we thought we would enjoy making the machine our own, so we put all efforts in it. It was tough to develop the rolling machine, but the results proved that we could do it if we tried. The future is unlimited.”

Mizuki devises efforts to make superior products. Manufacturing requires the skills of people involved in it. The trend for miniaturization of screws has settled down, and the process of harder materials is becoming a new challenge. The needs are changing so constantly that new machinery for new challenges will once again become necessary. To the question of whether he is going to develop new machinery when needed? “Of course, we will do it if it’s necessary,” Mr. Segawa replied.